How To Fill Long Screws In Box Without Manual Labor:Magnetic Long Screws Aligner Box Filling Machine

Introduction

Efficient packaging and handling of long screws are critical in various industries, including construction, automotive, and manufacturing. Traditional manual methods of filling boxes with long screws are labor-intensive, time-consuming, and prone to errors. To address these challenges, we introduce the Magnetic Long Screws Aligner Box Filling Machine, a state-of-the-art solution designed to automate this process and enhance productivity.

Problem Statement

Manual filling of long screws into boxes presents several challenges:

- Labor-Intensive: Requires significant manual effort and time.

- Inefficiency: Slows down the production line and leads to bottlenecks.

- Inaccuracy: Human error can result in inconsistent fill levels and packaging errors.

- Ergonomic Issues: Repetitive manual labor can lead to worker fatigue and injuries.

This paper explores how our Magnetic Long Screws Aligner Box Filling Machine solves these issues with advanced automation technology.

Product Overview

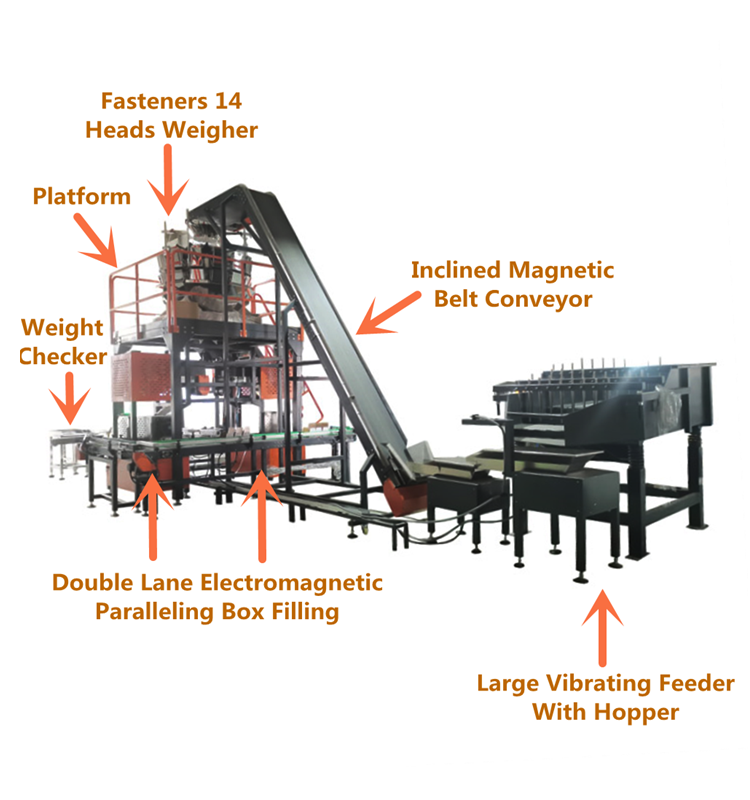

Our Magnetic Long Screws Aligner Box Filling Machine integrates several cutting-edge components to ensure efficient, accurate, and automated box filling:

- Vibration Feeder: This component smoothly feeds screws into the system, ensuring a consistent supply without jamming.

- Magnetic Belt Inclined Conveyor: The magnetic belt securely transports screws upwards and into the next stage of the process.

- Multi-Head Weigher: Precisely measures the screws to ensure each box is filled with the correct quantity.

- Magnetic Arrangement System: Aligns screws uniformly, facilitating organized and efficient packing.

- Box Filling System: Automatically fills boxes with aligned screws, ensuring uniformity and accuracy.

Benefits of the Magnetic Long Screws Aligner Box Filling Machine

- Increased Efficiency: Automation speeds up the filling process, significantly boosting productivity.

- Consistency and Accuracy: Advanced weighing and alignment systems ensure precise and uniform filling.

- Reduced Labor Costs: Automation minimizes the need for manual labor, leading to cost savings.

- Enhanced Safety and Ergonomics: Reduces repetitive strain on workers, promoting a safer workplace.

- Scalability: Easily integrates into existing production lines, scalable to various production demands.

Technical Specifications

- Vibration Feeder: Adjustable amplitude and frequency, designed to handle different screw sizes.

- Magnetic Belt Inclined Conveyor: High-strength magnets, customizable speed settings, and inclined design for efficient screw transport.

- Multi-Head Weigher: High-precision load cells, multiple weighing heads for simultaneous operations.

- Magnetic Arrangement System: Strong magnetic field, adjustable alignment settings, and compatibility with various screw lengths.

- Box Filling System: Automated filling mechanism, programmable fill levels, and user-friendly interface.

Use Cases and Applications

- Construction Industry: Efficiently packaging screws for large-scale projects.

- Automotive Manufacturing: Streamlining the packaging of screws used in vehicle assembly.

- Electronics Manufacturing: Precise filling of boxes with screws for electronic device assembly.

- Hardware Supply Companies: Automating the packaging process to meet high demand efficiently.

Conclusion

The Magnetic Long Screws Aligner Box Filling Machine represents a breakthrough in automation technology for packaging long screws. By integrating vibration feeding, magnetic transportation, precise weighing, and automated box filling, this machine addresses the inefficiencies and challenges associated with manual labor. Adopting this technology can significantly enhance productivity, accuracy, and safety in various industrial applications.

Call to Action

Discover the future of screw packaging with our Magnetic Long Screws Aligner Box Filling Machine. Contact us on WhatsApp 86 18929972670 for a demonstration and see how this innovative solution can transform your operations.